A key requirement was to use natural materials wherever possible - and also to at least give the appearance of age.

For the basic frame, rafters, studs and floor joists, I decided to use treated softwood. I had quickly dismissed green oak on the basis that it is difficult to work, blunts tools in seconds, is heavy, expensive and seems to discolour as soon as it gets anywhere near metal! However, I also decided to give all exposed timbers a dark oak woodstain.

.jpg)

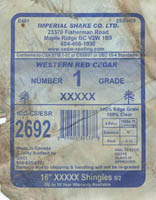

For the roof, there was really only one choice: No. 1 Blue Label Certigrade® Western red cedar shingles (see the Cedar Shake & Shingle Bureau website, which also provides an extremely useful installation manual). I decided against shakes, which are hand-split, on the basis that these have a more variable thickness (shingles are machine cut) and hence require an interlay on all courses.

Cedar shingles are around 16" long, of random widths, tapering from about 6mm at the butt end to 1 or 2 mm, and are typically fixed using stainless steel annular nails with a 5" exposure.

next

next